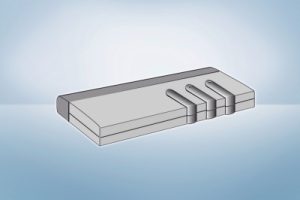

Series Gold

Custom DIN Rail Enclosure: The Perfect Solution for Your Industrial Needs

In the world of industrial automation and electronics, finding the right enclosure for your equipment is crucial. Whether you’re designing a control system or creating a custom solution, a DIN rail enclosure can be the key to ensuring the safety and functionality of your devices. In this article, we will explore the importance of custom DIN rail enclosures and why they are the ideal choice for your specific needs.

The Basics of DIN Rail Enclosures

Before delving into the customization aspect, let’s first understand what DIN rail enclosures are and why they are commonly used in industrial settings.

What is a DIN Rail? DIN, which stands for “Deutsches Institut für Normung,” is a set of standards used for various industries, including electronics and electrical engineering. A DIN rail is a standardized metal rail or mounting track used to mount electrical devices within an enclosure. These rails are made of materials like aluminum or steel. They are available in various sizes to accommodate different components.

Why Use DIN Rail Enclosures? DIN rail enclosures are favored in industrial applications for several reasons:

- Space Efficiency: They maximize the use of space within an enclosure, allowing for the installation of multiple devices in a compact area.

- Modularity: DIN rail systems are modular, making it easy to add or remove components as needed without extensive reconfiguration.

- Ease of Installation: Devices mounted on DIN rails can be easily snapped into place, reducing installation time and effort.

- Protection: These enclosures offer protection against environmental factors like dust, moisture, and electromagnetic interference, safeguarding sensitive electronic components.

Now that we’ve covered the basics, let’s explore the benefits of opting for a custom DIN rail enclosure tailored to your specific requirements.

The Advantages of Custom DIN Rail Enclosures

- Perfect Fit for Your Components

When you opt for a custom DIN rail enclosure, you have the advantage of designing it to perfectly fit your components. Whether you’re working with unique-shaped devices or have specific size constraints, customization ensures that everything fits precisely where it should.

- Enhanced Accessibility

In industrial settings, accessibility to your equipment is crucial for maintenance and troubleshooting. Custom enclosures can be designed with features such as hinged doors, removable panels, or transparent windows, allowing easy access to your devices when needed.

- Improved Cable Management

Custom DIN rail enclosures can include cable management solutions like cable glands, routing channels, and tie-down points. These features help keep your wiring organized and reduce the risk of damage or interference.

- Environmental Adaptability

Different industries and applications have varying environmental conditions. Customization allows you to select materials and features that provide the required protection against factors like extreme temperatures, corrosive substances, or heavy vibrations.

- Branding and Aesthetics

Your enclosure doesn’t have to be merely functional; it can also reflect your company’s brand and image. Custom enclosures can incorporate your logo, color schemes, and other design elements to create a cohesive and professional look.

- Cost Efficiency

While custom solutions may seem more expensive upfront, they can actually save you money in the long run. By ensuring that your enclosure meets your exact needs, you reduce the risk of costly modifications or replacements down the line.

How to Get Started with Custom DIN Rail Enclosures

To begin the process of obtaining a custom DIN rail enclosure, follow these steps:

- Define Your Requirements: Clearly outline your specific needs, including the dimensions, mounting options, protection levels, and any additional features you require.

- Work with a Specialist: Contact a reputable manufacturer or supplier specializing in custom enclosures. They can help you design and manufacture the ideal solution based on your requirements.

- Review and Approve Designs: Collaborate with the manufacturer to create detailed enclosure designs. Review and approve these designs to ensure they align with your expectations.

- Production and Testing: Once the design is finalized, the manufacturer will proceed with production. Quality control and testing processes will ensure that the enclosure meets industry standards and your specifications.

- Installation and Integration: After receiving your custom DIN rail enclosure, follow the manufacturer’s instructions for installation. Ensure that your devices fit securely and function as expected within the enclosure.

- Regular Maintenance: Schedule regular maintenance and inspections to ensure the continued performance and protection of your equipment.

- In conclusion, custom DIN rail enclosures offer a wide range of benefits for industrial applications. They provide the flexibility and precision needed to protect, organize, and maintain your valuable electronic components. By investing in a custom solution, you can enhance the efficiency, reliability, and longevity of your industrial systems while meeting your specific needs. So, when it comes to safeguarding your equipment and optimizing your operations, custom DIN rail enclosures are indeed the perfect solution.