Optimal Support for Your Din Rail: Exploring Din Rail Supports

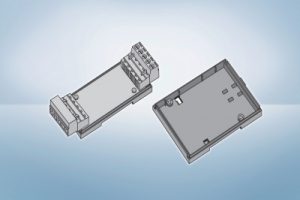

Supports for PCBs is the quickest and simplest method to assemble electronic equipment into closed racks. The supports are easily fastened onto a DIN rail by means of a clip. This 2-9 modular system allows different PCB dimensions according to customer requirements. Series 3600

Din rails play a crucial role in supporting various electrical components in industrial settings. To ensure the stability and longevity of your electrical installations, it’s essential to focus on the right infrastructure.

Understanding the Importance

This device serve as the backbone for mounting electrical devices in control panels and cabinets. The Din rail itself provides a standardized platform for the installation of components like circuit breakers, terminal blocks, and relays. However, the effectiveness of the entire system relies heavily on the quality and appropriateness of the Din rail supports.

These supports are designed to secure the Din rail in place, preventing vibrations, shocks, and other external factors from affecting the stability of the electrical components. Without proper support, there is a risk of misalignment and damage, leading to potential malfunctions and downtime.

Choosing the Right Din Rail Supports

Selecting the right device involves considering various factors. These may include the type of installation, the weight and size of the components, and the environmental conditions. Stainless steel supports are often preferred for their corrosion resistance, making them suitable for both indoor and outdoor applications.

Additionally, some Din rail supports come with insulation properties, adding an extra layer of protection to the electrical components. This is particularly crucial in environments where moisture and contaminants are present, as it helps prevent short circuits and other electrical issues.

Installation Tips

Proper installation is key to ensuring the effectiveness. Follow these steps for a secure and stable setup:

- Positioning: Before installation, carefully plan the positioning of the device to evenly distribute the weight of the components.

- Secure Fastening: Use appropriate fasteners to secure the supports in place. This prevents any movement that may occur due to vibrations or external forces.

- Regular Maintenance: Periodically inspect the product for signs of wear or damage. Replace any components that show wear and tighten fasteners if they become loose over time.

Advantages

- Enhanced Stability: Quality supports ensure that the Din rail remains stable, reducing the risk of misalignment and damage to components.

- Extended Lifespan: By providing reliable support, these components contribute to the longevity of the entire electrical system.

- Reduced Downtime: A stable and well-supported Din rail minimizes the chances of malfunctions, leading to decreased downtime and increased operational efficiency.

Conclusion

In conclusion, the role of this product is in maintaining the integrity of electrical installations cannot be overstated. Choosing the right supports and ensuring their proper installation is essential for the overall performance and longevity of your industrial electrical systems. By following best practices and investing in quality supports, you can optimize the stability and reliability of your Din rail-mounted components.